Cov khoom

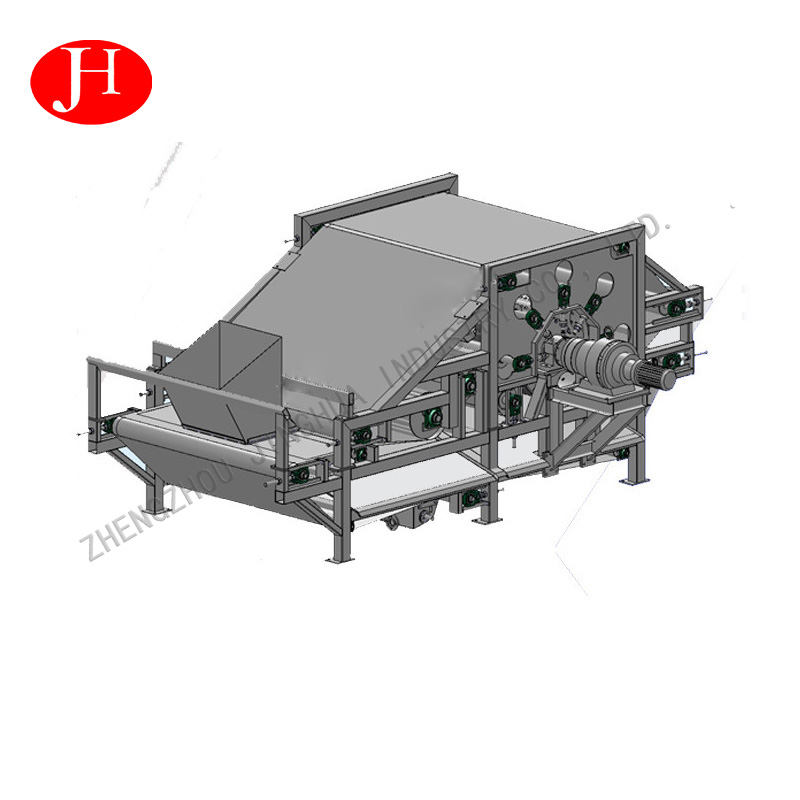

Fiber Dehydrator rau Starch Processing

Main technical parameters

| Qauv | Hwj chim (Kw) | Lim pluaj dav (mm) | Lim pluaj ceev (m/s) | Peev xwm (Ua ntej lub cev qhuav dej) (kg / h) | Dimension (mm) |

| TZD 150 | 3.3 | 1500 | 0-0.13 Nws | ≥5000 | 4900x2800x2110 |

| TZD 180 | 3.3 | 1800 | 0-0.13 Nws | ≥7000 | 5550x3200x2110 |

| TZD 220 | 3.7 | 2200 | 0-0.13 Nws | ≥9000 | 5570x3650x2150 |

| TZD 280 | 5.2 | 2800 | 0-0.13 Nws | ≥10000 | 5520x3050x2150 |

Nta

- 1Cov khoom lag luam yog tsim los ntawm lub tuam txhab, nrog rau kev tshawb fawb tshawb fawb ntawm Henan University of Technology.

- 2Wedge-shaped feeder tuaj yeem ua kom cov ntaub ntawv sib npaug sib npaug ntawm cov pluaj lim nrog cov tuab tuaj yeem kho tau.

- 3Lub cev qhuav dej rolling system ua seamless raj thiab qhwv los ntawm cov roj hmab zoo hnav-resistant, Nws yog kev ntseeg siab nrog kev pab cuam lub neej ntev.

Qhia Paub meej

Cov qos yaj ywm residue pub hopper yog flatly nteg nyob rau hauv qis lim txoj siv los ntawm lub wedge-shaped feeding seem.

Tom qab ntawd cov qos yaj ywm residue nkag mus rau qhov chaw nias thiab lub cev qhuav dej. Cov qos yaj ywm residue yog sib npaug ntawm ob txoj hlua lim thiab nkag mus rau thaj tsam wedge thiab pib compress thiab dehydrate. Tom qab ntawd, cov qos yaj ywm seem yog tuav los ntawm ob txoj hlua lim, uas sawv thiab poob rau ob peb zaug. Cov hauj lwm ntawm cov txheej sab hauv thiab sab nrauv ntawm ob lub lim siv ntawm cov menyuam hloov tas li, yog li ntawd cov qos yaj ywm residue txheej yog tas li dislocated thiab shear, thiab ib tug loj npaum li cas ntawm cov dej yog squeezed tawm nyob rau hauv lub nro quab yuam ntawm lub lim siv. Tom qab ntawd cov qos yaj ywm residue nkag mus rau qhov chaw nias thiab dewatering. Nyob rau hauv qhov kev txiav txim ntawm ob peb nias chais nyob rau sab sauv ntawm tus tsav tsheb rau cov menyuam, dislocation shear thiab extrusion yog tsis tu ncua tsim.thaum lub sij hawm nias txheej txheem, cov qos yaj ywm dregs tau yooj yim tshem tawm ntawm lub lim siv.

Cov qos yaj ywm residue raug xa mus rau cov cuab yeej scraping los ntawm cov menyuam rov qab, thiab tom qab raug khawb tawm los ntawm cov cuab yeej scraping, nws nkag mus rau ntu tom ntej.

Scope ntawm daim ntawv thov

Qos yaj ywm starch, tapioca starch, qos starch, nplej hmoov txhuv nplej siab, pob kws starch, pea starch, thiab lwm yam (starch suspension) starch ntau lawm qhauj.